Sublimation and Print Fabric Innovations: New Sustainable and Recyclable Options

Sublimation and print fabric innovations are becoming increasingly sustainable and environmentally friendly. Many companies are now using recycled polyester and other sustainable materials in their sublimation and print fabrics.

One example is the use of recycled PET bottles to create polyester fibers. This not only reduces waste but also reduces the need for virgin materials, which can have a significant environmental impact. Some companies are also using plant-based fibers, such as bamboo and hemp, to create sustainable sublimation and print fabrics.

Another innovation in sustainable sublimation and print fabrics is the use of eco-friendly dyes and inks. Traditional dyes and inks can be harmful to the environment, but new eco-friendly options are being developed that are biodegradable and less toxic. Some companies are also using digital printing techniques, which use less water and energy compared to traditional printing methods.

In addition to sustainability, sublimation and print fabric innovations are also improving the quality and performance of these fabrics. New technologies are being developed to enhance the color vibrancy, durability, and moisture-wicking properties of sublimation and print fabrics, making them ideal for sportswear, activewear, and other performance apparel.

Overall, the use of sustainable materials and eco-friendly processes in sublimation and print fabrics is a positive step towards a more environmentally conscious fashion industry.

How to Care for Your Sublimation and Print Fabric Clothing and Textiles

To care for sublimation and print fabric clothing and textiles, follow these tips:

Machine wash in cold water with similar colors: This helps prevent color bleeding and fading.

Use mild detergent: Harsh detergents can damage the sublimation and print design on the fabric.

Avoid fabric softeners: Fabric softeners can leave a residue on the fabric that can impact the vibrancy of the sublimation and print design.

Hang dry: Avoid using a dryer as the heat can damage the sublimation and print design.

Iron carefully: If you need to iron your sublimation and print fabric item, do so inside out at a low temperature. Direct heat can cause damage to the design.

By following these care instructions, you can maintain the quality and vibrancy of your sublimation and print fabric clothing and textiles.

Sublimation and Print Fabric: How It Enhances Performance and Aesthetics

Sublimation and print fabric technology has revolutionized the performance and aesthetics of clothing and textiles. Here are some of the ways sublimation and print fabric enhance performance and aesthetics:

Design flexibility: Sublimation and print fabric technology allows for virtually limitless design possibilities, from intricate patterns and designs to photorealistic prints. This provides more flexibility and options for designers, allowing them to create unique and visually appealing garments and textiles.

Durability: The sublimation and print designs are embedded into the fabric fibers, creating a durable and long-lasting print that won't peel, crack, or fade over time. This makes sublimation and print fabric ideal for performance apparel and sportswear that requires frequent washing and wear.

Breathability: Sublimation and print fabric technology allows for a breathable, lightweight, and moisture-wicking fabric that is ideal for athletic wear. The dye sublimation process doesn't add any additional layers to the fabric, allowing it to retain its moisture-wicking properties and breathability.

Eco-friendly: Sublimation and print fabric technology can also be eco-friendly, with the use of water-based inks and dyes that are safer for the environment and human health.

Overall, sublimation and print fabric technology offers a wide range of benefits that enhance the performance and aesthetics of clothing and textiles, making it a popular choice in various industries, from sportswear to fashion.

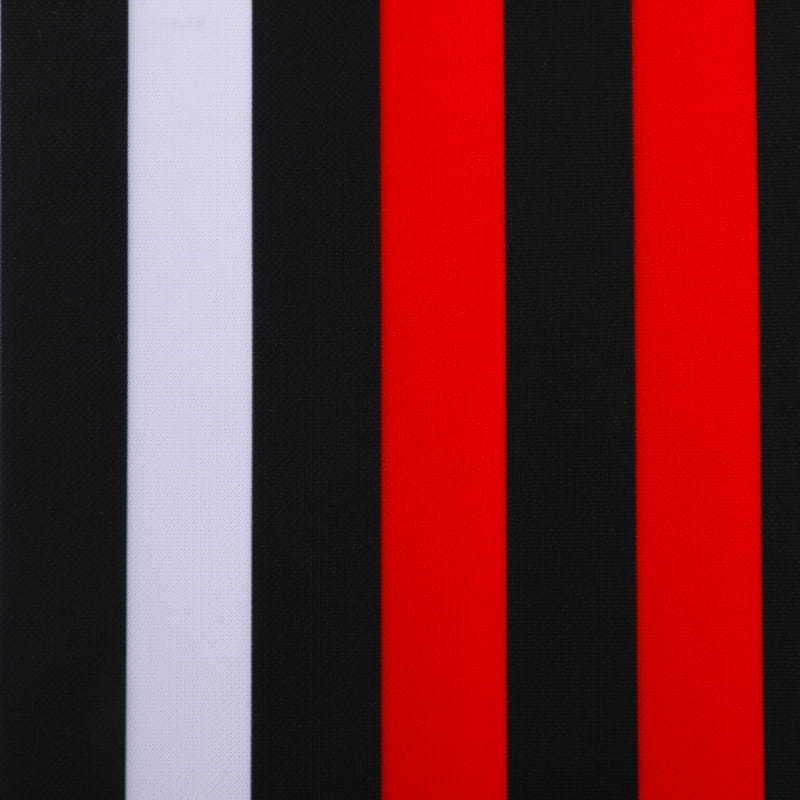

Sublimation Print 100% Polyester Pique Double Knit Fabric

Sublimation Print 100% Polyester Pique Double Knit Fabric

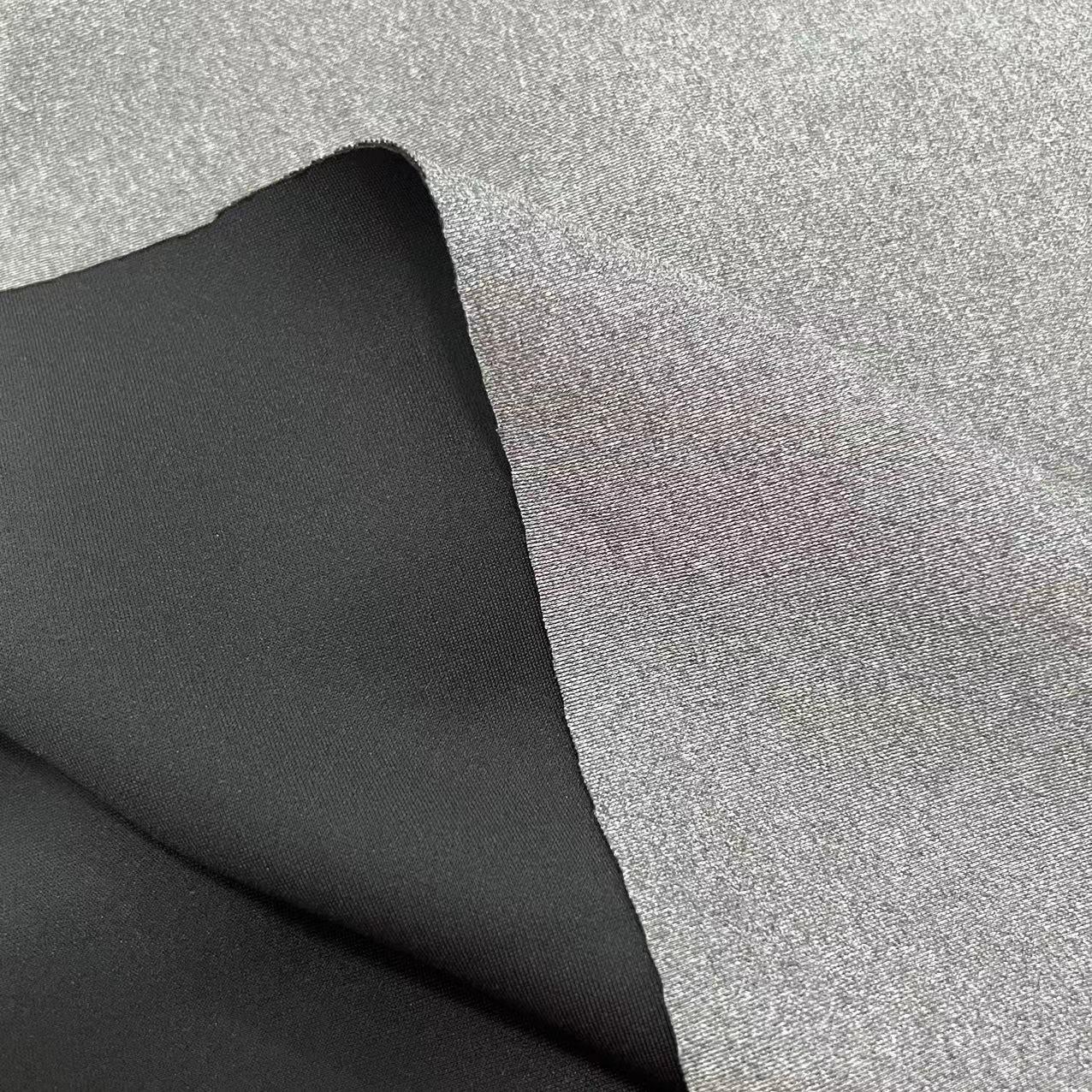

100% Polyester Brushed Printing Knit Fabric

100% Polyester Brushed Printing Knit Fabric

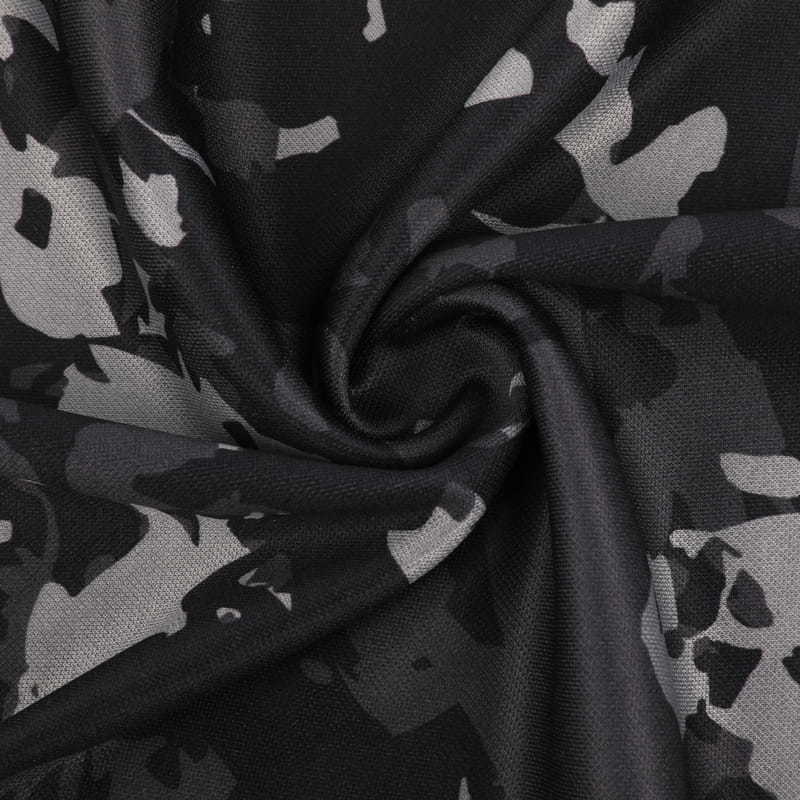

Print Eyelet Mesh 100% Polyester Knitted Fabric

Print Eyelet Mesh 100% Polyester Knitted Fabric

English

English 中文简体

中文简体.jpg?imageView2/2/format/jp2)