100% Polyester Brushed Double Knit Fabric

100% Polyester Brushed Double Knit Fabric

100% polyester brushed double knit fabric is front-side plain with back-side brushed. The fabric is ...

Polyester Brushed Jacquard Textured Knit Fabric

Polyester Brushed Jacquard Textured Knit Fabric

Polyester brushed jacuqard textured knit fabric is a knid of double knit fabric. The design and text...

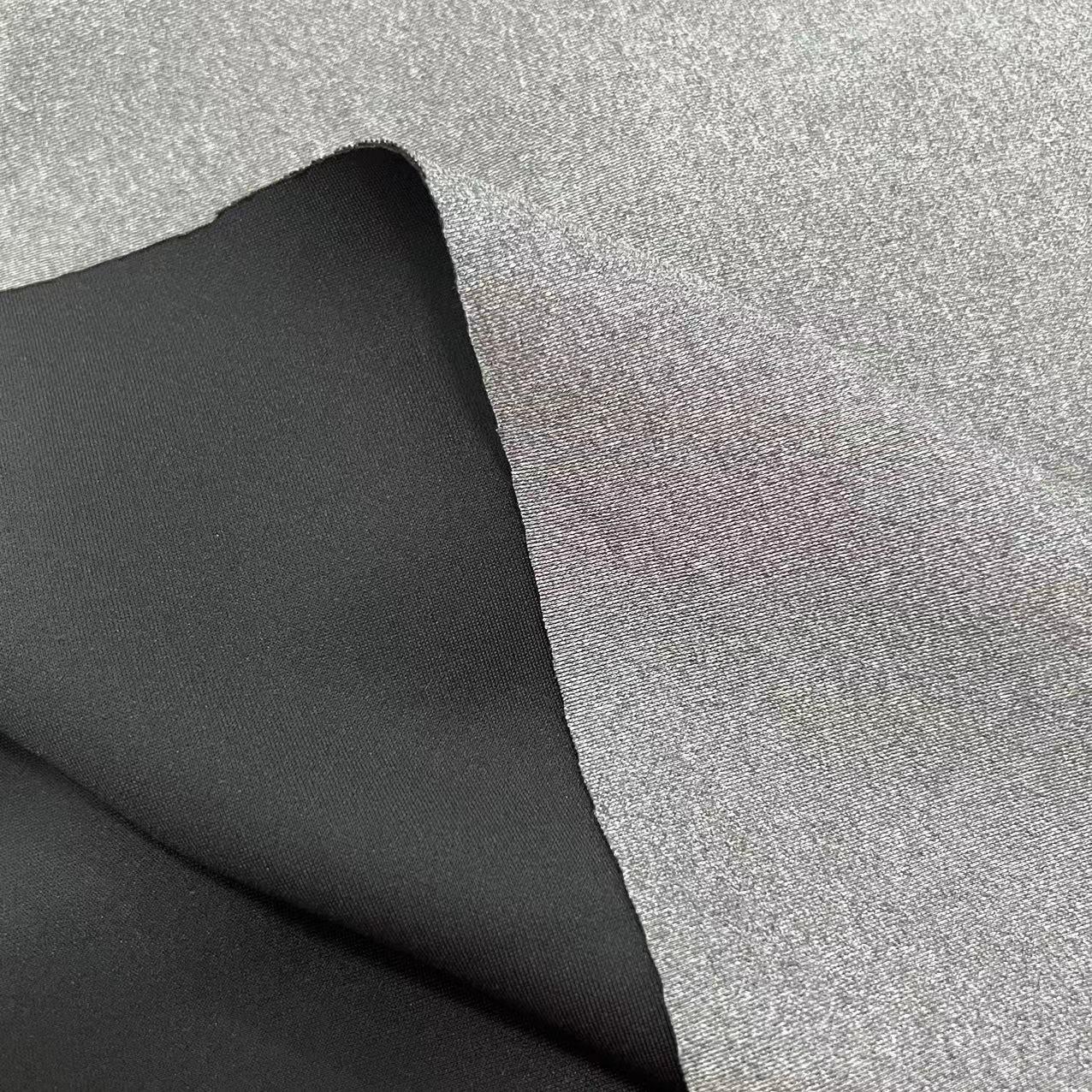

Cationic Polyester Brushed Knitted Fabric

Cationic Polyester Brushed Knitted Fabric

The composition of this polyester brushed fabric is cationic polyester yarn on the front and normal ...

Polyester French Terry Circular Knitted Fabric

Polyester French Terry Circular Knitted Fabric

Polyester french terry fabric is considered a midweight fabric, which means that it is heavier than ...

Solid Polyester Brushed Waffle Knit Fabric

Solid Polyester Brushed Waffle Knit Fabric

This solid polyester brushed waffle knit fabric is brushed on one side and plush to the touch. Brush...

100% Polyester Heather Melange Brushed Knitted Fabric

100% Polyester Heather Melange Brushed Knitted Fabric

The composition of this polyester brushed fabric is cationic polyester yarn on the front and normal ...

260Gsm Imitation Cotton Polyester Circular Knitted Fabric

260Gsm Imitation Cotton Polyester Circular Knitted Fabric

The fabric is made by imitation cotton, which is 100% polyester but has a real cotton look and feel....

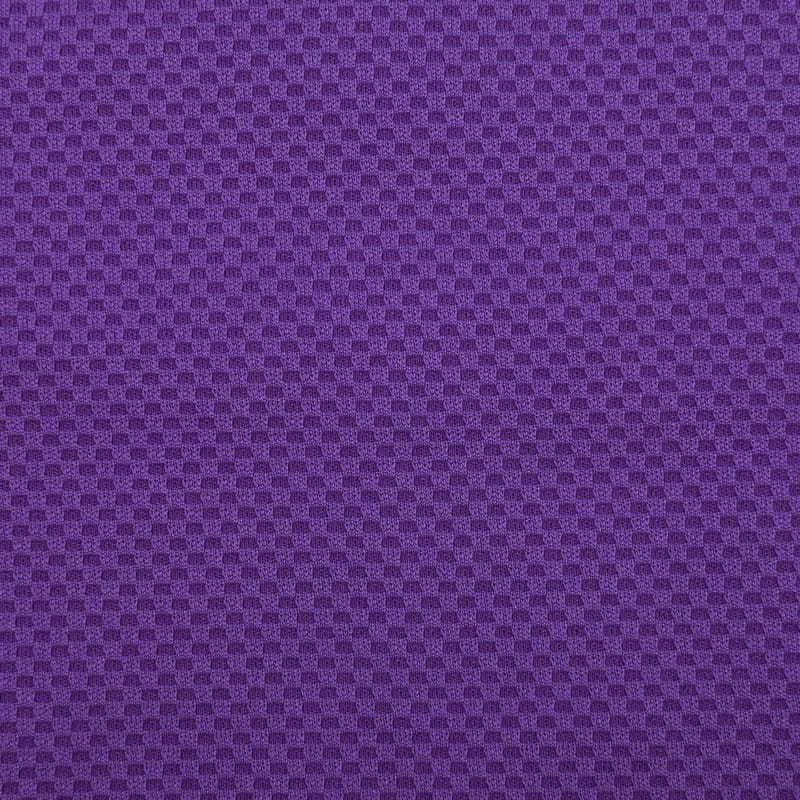

220Gsm Pique Fabric 100% Polyester Circular Knitted Fabric

220Gsm Pique Fabric 100% Polyester Circular Knitted Fabric

Pique fabric is extremely absorbent, durable, breathable and easy-care fabric.It's an ideal as a mat...

250Gsm 100% Polyester Eyelet Mesh Fabric 3 Tuck For Active Wear

250Gsm 100% Polyester Eyelet Mesh Fabric 3 Tuck For Active Wear

Eyelet mesh/bird eye/mock mesh/flat back fabric is one of the most popolar circular knitted fabric. ...

190Gsm 100% Cationic Polyester 2 Color Bird Eye Mesh Fabric

190Gsm 100% Cationic Polyester 2 Color Bird Eye Mesh Fabric

This 100% cationic polyester eyelet mesh have 2 color effect.Lightweight, breathable, with wicking f...

Sports Polyester Shiny Mesh Circular Knit Fabric

Sports Polyester Shiny Mesh Circular Knit Fabric

This sports polyester shiny mesh is semi-dull in the front side and shiny in the back side, which sh...

Polyester Wicking Stripe Double P.K Circular Knit Fabric Textile For Garment Shirt Polo Athleisure

Polyester Wicking Stripe Double P.K Circular Knit Fabric Textile For Garment Shirt Polo Athleisure

Polyester wicking stripe double P.K circular knit fabric textile, This 100% polyester circular knitt...

English

English 中文简体

中文简体.jpg?imageView2/2/format/jp2)